Proactive Air Compressor

Maintenance in Florida

Air Compressor Maintenance

The Importance of Regular Maintenance

Need a rapid response air compressor repair?

Your air compressor system is the heartbeat of your operation — and like any critical equipment, it needs consistent care to perform at its best. At American Air Compressor, we provide scheduled equipment maintenance services that prevent unexpected breakdowns, lower operating costs, and improve overall system performance. Especially in Florida’s hot and humid climate, routine maintenance is essential to combat excess moisture, overheating, and pressure loss.

Don’t let a bad compressor keep your business from progressing

Benefits of Preventative Maintenance

Keep your equipment running efficiently, reduce costly downtime, and extend the lifespan of your system with expert preventative maintenance from American Air Compressor.

Increased Efficiency & Lower Energy Costs

A clean, well-maintained air system runs more efficiently, consuming less power while delivering more reliable pressure. Preventative service helps eliminate energy waste caused by clogged filters, leaks, or overheating.

Reduced Downtime & Emergency Repairs

Avoid costly equipment failures with proactive service that catches issues before they escalate. Our regular inspections minimize the risk of production-stopping emergencies and extend the time between major repairs.

Extended Equipment Life & Warranty Protection

Routine maintenance helps maximize the lifespan of your compressor system and ensures continued compliance with manufacturer warranties, protecting your investment long-term.

Florida’s high humidity, salty air, and heat present unique challenges to compressed air systems. Without regular maintenance, moisture buildup and corrosion can lead to early failure and performance degradation. Our technicians understand local conditions and tailor service to combat environmental stressors while ensuring your system meets regional safety and performance standards.

Preventative Maintenance Services

Our maintenance plans are tailored to the specific needs of your facility and equipment type. Every visit includes:

Comprehensive System Inspection

We inspect all components for wear, vibration, overheating, leaks, and pressure inconsistencies.Filter & Fluid Management

We replace air/oil filters, check coolant levels, and ensure proper lubrication to keep your compressor running smoothly.Leak Detection & Air System Audit

We test for pressure losses and air leaks, helping you cut down on wasted energy and identify inefficiencies.Electrical & Safety System Check

We inspect wiring, relays, control panels, and pressure safety valves to ensure everything meets operating standards.Custom Maintenance Scheduling

Plans are based on your runtime hours, facility needs, and equipment type. We create a proactive maintenance calendar so you don’t have to worry.

Industries That Rely on Preventative Maintenance

- Manufacturing & Processing Plants

- Food & Beverage Facilities

- Medical & Dental Clinics

- Automotive & Body Shops

- Machine Shops & Fabricators

- Woodworking & Countertop Producers

- Agriculture & Landscaping Operations

Our Maintenance Process

Initial System Assessment

We begin with a thorough evaluation of your compressor system, documenting equipment age, make, and any existing issues.

Maintenance Plan Development

Based on your usage and environment, we create a customized service schedule that fits your production flow and budget.

Routine Service Visits

Our trained technicians perform regular service at scheduled intervals, replacing parts, cleaning systems, and checking functionality.

Post-Service Reporting

After each visit, you receive a detailed report outlining work performed, any detected issues, and recommendations for improvements.

FAQs About Compressor Maintenance

How often should I have my compressor serviced?

Most systems should be checked every 2,000–4,000 operating hours or at least twice a year, depending on usage and environment.

Do you offer annual maintenance contracts?

Yes. We offer flexible maintenance plans based on your facility’s size, runtime hours, and budget.

Can you service equipment from other vendors or brands?

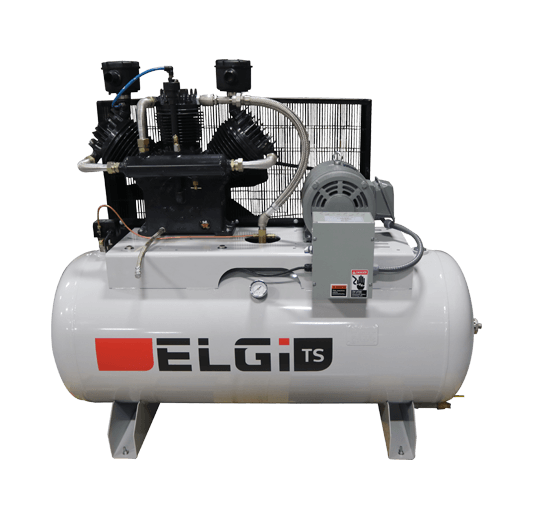

Absolutely. We work on all major brands, including ELGi, Quincy, OZEN, Atlas Copco, Ingersoll Rand, and more.

Is preventative maintenance really worth the cost?

Yes — it helps you avoid emergency repairs, save on energy, and protect your long-term investment.

Do you offer documentation for safety and compliance audits?

Yes, our service reports are ideal for maintenance logs, insurance records, and OSHA compliance.

Serving Jacksonville, St. Augustine, and surrounding Northeast Florida counties.

Get Your Equipment Protected — Schedule Preventative Maintenance Today!

Don't wait for costly breakdowns to impact your workflow. Let American Air Compressor help you stay ahead with reliable, scheduled compressor maintenance. We service all major brands, including ELGi, Quincy, and OZEN.